Out of University and Straight Into Orbit

The President Is Visiting the TUM Start-up Isar Aerospace

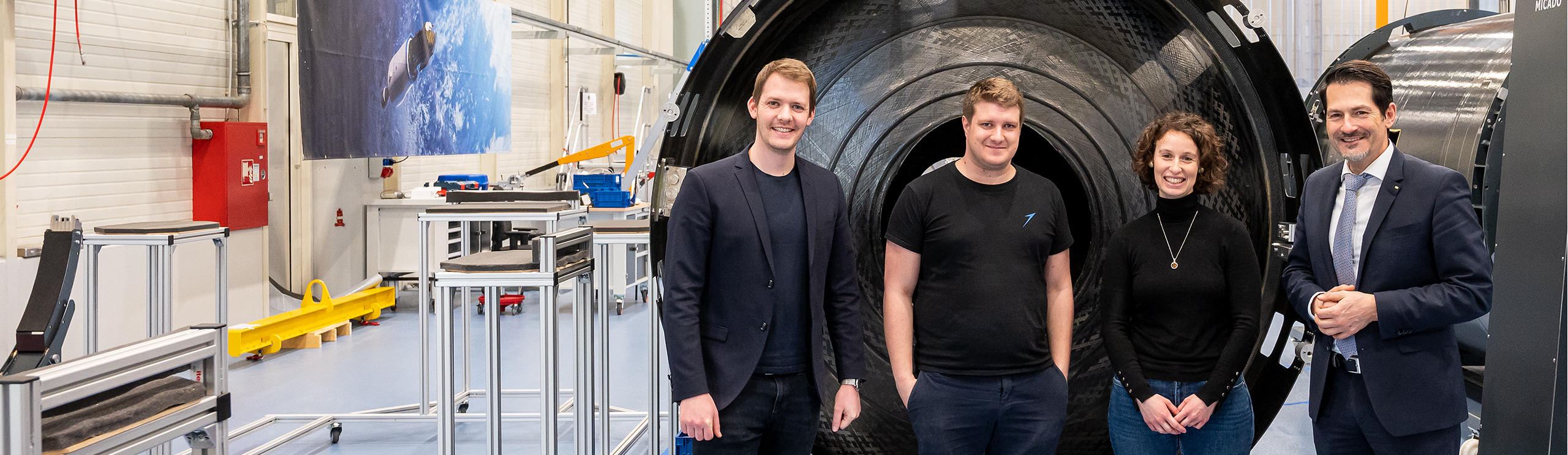

TUM President Thomas F. Hofmann (r.) visited the production halls of the TUM start-up Isar Aerospace. The two founders Daniel Metzler (left) and Josef Fleischmann (2nd from right) as well as engineer Lucrezia Veggi gave him a tour of the company (Photo: Astrid Eckert/TUM).

——-

After a short safety briefing and being fitted with safety shoes, the group enters the factory hall through a heavy steel door. The many machines here produce a steady droning noise. Around 70 people work in manufacturing at Isar Aerospace. Some sit focused intently at their workstations, filing workpieces or soldering parts. Elsewhere, groups of employees stand together, either discussing a shipment of parts or engrossed in a construction design.

Daniel Metzler: Yes, we have grown quite a bit. We opened the hall with just one machine in September 2020, and within just one year we have built a complete, highly automated production facility to produce our rocket ‘Spectrum’. Back then we had 90 employees, now we have almost 250.

Josef Fleischmann: From the very beginning, it was important to us to be more cost-efficient than the established industry by using new materials and technologies. Our manufacturing process is based on a high level of automation and state-of-the-art technologies such as additive manufacturing and the use of carbon fiber composites. The most complex parts of our rocket engines are 3D printed using high-performance metals. This gives us great flexibility in design and the shortest possible lead times.

Thomas F. Hofmann: Your entire setup really is tremendously innovative. You are trying out new materials, use new production methods, and come up with excellent test results.

Daniel Metzler: That is our great advantage as a start-up. We are able to react quickly and flexibly. We can be bold enough to take risks, just try something out and then change our course again. We have set ourselves the goal of pushing the limits of what is possible and at the same time being second to none in terms of development speed.

Josef Fleischmann: Here in our facilities and at our company-owned sites, we are able to test our designs and include many iterative loops. This lets us know very early on whether things really work, and we are able to eliminate many mistakes in a better way than if we developed only on paper.

The exchange with young talents from TUM is very important to President Thomas F. Hofmann. He was therefore pleased to get to know Isar Aerospace's production methods and the motivated founders better (Picture: Astrid Eckert/TUM).

Students have to be given the courage to break new ground, to think beyond the well-trodden paths, so that they can become pioneers like you.

Josef Fleischmann: Yes, that is true. We met at WARR. We built rocket engines and used them to launch small test rockets. At some point, we were approached by companies that wanted to buy our engines. We then asked ourselves: Why are industrial companies interested in buying rocket engines from students, can’t they make their own? And it occurred to us that if there is a need for rocket engines, then there certainly is a need for an entire launch vehicle. It quickly became clear to us that in the decades to come, a competitive and diversified space ecosystem would be critical for industry and humanity alike. And on the other hand, we realized that Europe did not yet have affordable and flexible access to space. Thus, the idea for Isar Aerospace was born.

Daniel Metzler: My time at WARR was absolutely formative, I keep emphasizing that. Here, I was able to pursue my interest in space technology in a business-related setting and put ideas into practice right away. Especially the exchange with the other members of the working group, the trial and error and just going for it, have further strengthened my belief in the possibilities of space technology and also my belief in our abilities to pull it off. When we first started Isar Aerospace, we were able to get some of our former fellow students at WARR interested in the company, and they have been on board since day one. We still recruit from the WARR working group and TUM’s Aerospace Engineering department – because they provide top-notch education.

Thomas F. Hofmann: At TUM, student initiatives are a natural part of the education, even if they are not part of the curriculum. Many of the more than 50 student initiatives at TUM are very active and highly successful, among them the TUM Hyperloop or the TUM Boring Team, which have broken numerous records in the last few years. We are proud of all these impressive student projects that are being created at our university. This is what sets us apart. We need to promote the process of testing ideas without constraints and working together on such challenges, and that’s where I see my duty as president. Students have to be given the courage to break new ground, to think beyond the well-trodden paths, so that they can become pioneers like you.

Lucrezia Veggi: Pretty much from day one. I was one of Isar Aerospace’s first employees. I met Daniel and Josef while still at TUM and when I heard about the start-up idea, I was instantly thrilled. And of course I recognized the opportunities that are available here – namely, that I can be at the forefront of groundbreaking innovations.

Thomas F. Hofmann: As young entrepreneurs you are also an example for a certain attitude to your employees and show that you are fearless enough to try out things that may seem impossible at first. If we want to remain competitive and agile in the future, we need more people in Germany and Europe with this kind of attitude. How did you manage to put together such a great team in such a short time?

Josef Fleischmann: Without the passion and motivation that we as a team put into working hard every day to achieve our ambitious goal – the first test flight of our rocket ‘Spectrum’ – we would, no doubt, not be where we are today. The founding team and many of our engineers already know each other from their student days at TUM and their work at WARR, and have been with us since the beginning. Working together to build up such a large project is a bonding experience. And the many new employees who have joined the team over the past years have chosen us primarily because our vision has convinced them and they can actually make European space history here. We are very happy to recruit TUM graduates because they come with the right mindset, are eager to get to work, and don’t let setbacks get them down. You are more than welcome to send us more TUM Alumni (laughs).

Thomas F. Hofmann: It’s part of the game that things sometimes don’t work out and you have to start all over again. Every pioneer and every innovator, whether at university, in business or elsewhere, needs to be able to tolerate a certain amount of frustration.

Daniel Metzler: Indeed. Even in the student project, mistakes were not only part of the learning process, but an essential component for our technical developments. And that is still the case here at Isar Aerospace!

CEO and TUM alumnus Daniel Metzler explains to Thomas F. Hofmann how Isar Aerospace takes care of quality assurance (Picture: Astrid Eckert).

We are incredibly proud of how far we have come. However, it’s still a huge task. One is the challenge of building something as complex as a rocket in the first place and making it work.

Josef Fleischmann: There is a lot of competition and some of them are very renowned companies, but as a start-up we have the advantage that we can experiment a lot more. We have other challenges, we have to build our reputation first, but we are nimble and not afraid to explore a completely new avenue if the first one doesn’t work. Our finished rocket, part of which you see here, will end up being only two meters wide in diameter.

Daniel Metzler: We are incredibly proud of how far we have come. However, it’s still a huge task. One is the challenge of building something as complex as a rocket in the first place and making it work. But also at a market level, companies like us in the space and satellite industry still have to overcome many obstacles. In the area of financing but also in terms of the legal framework. A lot still needs to happen here to create a competitive market in Europe that can make a sustainable contribution to technological innovation and progress.

Josef Fleischmann: I don’t think many people are aware of how much satellite technology already defines our everyday lives. Be it in the field of Earth Observation, in climate protection or for communication. Just recently, we were all reminded of its immense importance when Starlink, SpaceX’s satellite Internet, made its technology available after the Russian invasion of Ukraine, thus ensuring that the people in Ukraine remain able to communicate and can continue to take action. Conversely, of course, this carries great risks of being dependent on other companies and states. It is therefore essential that we in Europe have the necessary resources to be able to launch satellites into space on our own and to set up satellite systems – not only, but also for defense purposes.

Thomas F. Hofmann: You have already mentioned environmental protection. One of the first satellites that will go into space with you will be from OroraTech, also a start-up by TUM Alumni. This company is dedicated to using satellite technology to detect forest fires and bushfires as early as possible. I found it remarkable that two companies founded by TUM Alumni are working together on this venture.

Daniel Metzler: We have known Thomas Grübler from OroraTech for many years and we have been in close contact all this time. The fact that this cooperation came about in the end has, I think, mainly to do with our convincing concept and progress as a company and is a strong sign of the interest and trust in Isar Aerospace’s technology and expertise. Of course, this cooperation also stands for what we collectively embody: innovation and know-how for satellite-based applications from Europe that improve life on earth. The fact that with OroraTech we were able to win a company which was founded by TUM Alumni, as well is something very special to us and signifies the potential and innovative power of the TUM ecosystem.

Thomas F. Hofmann: In any case, I think it is very important that we in Europe take on a new leadership role in aerospace technology. This is the only way we can make a difference and protect the world as a whole even better. In July, we opened the first dedicated building of the Department of Aerospace & Geodesy in the TUM School of Engineering and Design here next door to you in Ottobrunn. Over the next few years, the department is set to become the largest and best of its kind in Europe. What are your next steps?

Daniel Metzler: We are currently in a critical phase, with further tests of our internally designed and developed drive pending. Between now and the launch, we are facing a lot of challenges – whether it’s adjusting things during development on the basis of the test results or whether a certain approval for the infrastructure we need is once again taking longer than expected. But that’s nothing that will throw us off track.

It takes a healthy dose of respect. Otherwise we would be foolish.

Thomas F. Hofmann: You are all highly ambitious and have great aspirations. But from what I’ve seen of you today, I’m convinced you will succeed. Do you sometimes worry that you might not make it?

Josef Fleischmann: It takes a healthy dose of respect. Otherwise we would be foolish. Also in everyday life there are times when we experience some frustration, when something doesn’t work out the way we imagined or mistakes happen. But I am always encouraged by the fact that many people here are putting their heart and soul into achieving one common goal. Together, we have developed an outstanding product.

Thomas F. Hofmann: Would you fly into space yourself if you could? Personally, I wouldn’t rule it out. It must be very touching to look back at our planet from above.

Daniel Metzler: Space intrigues me. The vastness, the many unexplored things out there – and the many opportunities that easier access to space opens up for us. I would like to make my contribution to this. But my skills are more in the area of engineering here on Earth. That’s why for the time being, a space flight is not on my list of priorities (laughs).

The production halls of Isar Aerospace are located in the direct vicinity of the new building of the TUM Department for Aerospace and Geodesy in Ottobrunn (Picture: Astrid Eckert/TUM).